Engine repair

Engines

Why Recondition your engine over a used swap?

When faced with engine issues, vehicle owners often weigh the options between a straight swap with a used engine and opting for engine reconditioning. While a straight swap might seem like a quick fix, reconditioning your engine offers a host of advantages that go beyond mere immediate convenience. It involves a detailed process where the engine is dismantled, inspected, cleaned, and any worn or damaged parts are repaired or replaced. This not only restores the engine to its optimal condition but also often enhances its performance and efficiency. Here are several compelling reasons why reconditioning your engine could be a more advantageous choice over a straight swap:

If you have any questions, feel free to call us or get free quote.

This is the quickest and easiest way to get your quote

Oil & Filter

Main & Big End Bearings Replaced

Crankshaft Polish

Stem Seals Replaced

Valves, cut and reseated

Piston Rings Replaced

Engine Block & Liners inspected

Cylinder Head pressure tested & Skimmed

Connecting Rods Inspected

Timing Kit Replaced

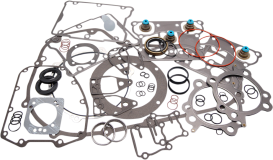

Gasket Kit Replaced

Crankshaft Seals Replaced

Guaranteed Quality

Reconditioned engines undergo a thorough process of disassembly, cleaning, inspection, and replacement of damaged or worn parts. This ensures that the engine you receive is in excellent condition, often comparable to a new engine in terms of performance and reliability.

Warranty Coverage

Many reconditioned engines come with a warranty, offering peace of mind and protection for your investment. In contrast, used engines often have little to no warranty, leaving you vulnerable to unforeseen issues.

Cost-Effectiveness in the Long Run

While a reconditioned engine might have a higher upfront cost compared to a used engine, the long-term reliability and potential for fewer repairs can make it more cost-effective over time.